Promake®GVT single head filling cosmetic, cream, paste Fully automatic filling machine

Promake®GVT single head filling cosmetic, cream, paste Fully automatic filling machine

- Regular price

- $0.00 USD

- Regular price

-

$0.00 USD - Sale price

- $0.00 USD

- Unit price

- per

Promake®GVT cosmetic, cream, paste Fully automatic filling machine

Application of the automatic filling machine:

This filling machine can be used to fill various high and low viscosity liquid and cream material:

Cosmetics: Shower gel, shampoo, facial cream, etc.

Food: margarine, chocolate, honey, etc.

Pharmacy:Injection, Antibiotics, Oral Solutions, etc.

Features and Advantages:

1. With new-designed figure,and compact structure.

2. High productivity.

3. The filling head can descend and fill automatically and then ascend quickly.

4. The conveyor belt is driven by braking motor and it stops when filling conveyor.

5. The filling machine runs lightly and fluently ,and it does not fill without bottle.

6. It can count the filling times automatically.

Technical Parameters of the automatic filling machine:

|

1.Main parts |

A filling machine(With dustproof Hood)and 114mm wide standard conveyor |

|

2.Working Mode |

Quantitative piston type filling automatic bottle feeding, automatic filling, automatic material feeding system |

|

3.Capacity |

100ml bottle:10-40pcs/min(parameters:bath lotion base on 25ºC,viscosity 10pa.s for the test standard,Sufficient material is requested by the factory for an over 10 minutes test before delivery. |

|

4.Features |

Photoelectric system for bottle feeding & returning, upper material feeding and check-valve free mechanical structure, a large gas tank at the bottom ensures continuously efficient and stable production. |

|

5.Convenience |

large adjustment mechanism(Including standard 114 widened conveyor, hand wheel lifting adjustment device, integral hand wheel adjustment device, single fine-tuning device)for frequent replacement of bottles. |

|

6.Control |

Man-machine touch interface, additional guided tuning module and fault diagnosis module enable convenient operation and maintenance. |

|

7.Structure |

Attractive appearance design,Compact structure Simple maintenance,no special tools required |

|

8.Warranty |

All parts warranty for one year after delivery(except wearing parts) |

|

9.Power |

220V 50HZ 1KW |

|

10.Gas source |

After drying, working pressure≥6kg/cm2, Gag consumption changes with gross output. |

|

11.Weight |

About 350kg |

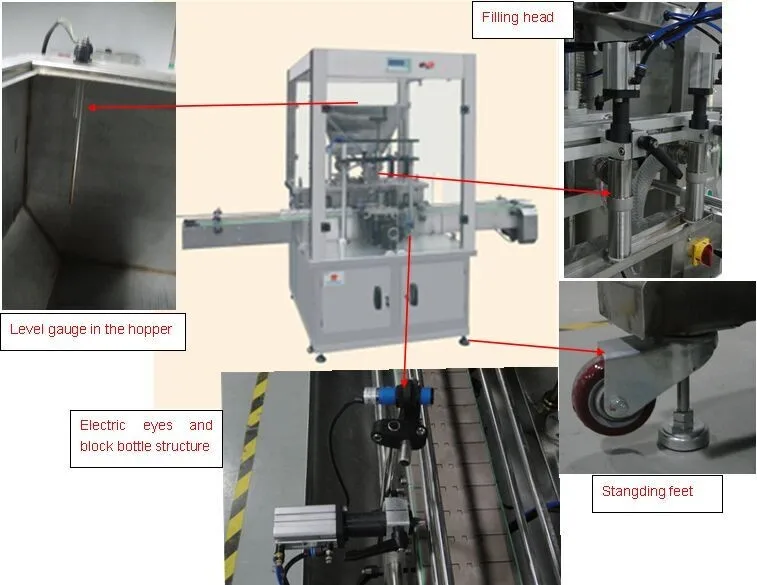

Reference Pictures

MOQ: 1 Set

Delivery Time: 25 working days after deposit

Payment: T/T, Western Union, Paypal, LC are welcome. 50% for deposit, 50% before shippment.

Chat with us directly via Whatsapp:+86-18922771775 for more info are welcome, we are glad to be of help.

Why Choose Us (PMK)

1) We as a manufacturer are specialized in all kinds of vacuum emulsifying mixer.

2) Good experience over 12 years to make cosmetics,pharmaceutical,food equipment.

3) Good experience of OEM & ODM for our customers.

4) Our components come from famous brands like:ABB, SIEMENS, Danfoss, Schneider, Burgmann, GRUNDFOS, FLENDER, NSK, Omron, MITSUBISHI ELECTRIC,etc.

5) Provide best price&fast delivery.

6) We manufacture many kinds of equipment,such as Water tank,storage vessel, emulsifying machine, homogenizer, vacuum emulsifier, shampoo mixer,detergent mixer,liquid filling machine,cream filling machine,labeling machine, inkjet printer,conveyor,pump,etc.

Couldn't load pickup availability